小型表面贴片型贴片晶振,较适合使用在汽车电子领域中,比如车载晶振,也是特别要求高可靠性的引擎控制用CPU的时钟部分.低频晶振可从8MHz起对应,小型,薄型具备强防焊裂性,石英晶体在恶劣严酷的环境条件下也能发挥稳定的起振特性,产品本身具有耐热,耐振,耐撞击等优良的耐环境特性,满足无铅焊盘以及高温回流温度曲线要求,符合AEC-Q200认证.

小型表面贴片型贴片晶振,较适合使用在汽车电子领域中,比如车载晶振,也是特别要求高可靠性的引擎控制用CPU的时钟部分.低频晶振可从6MHz起对应,小型,薄型具备强防焊裂性,石英晶体在恶劣严酷的环境条件下也能发挥稳定的起振特性,产品本身具有耐热,耐振,耐撞击等优良的耐环境特性,满足无铅焊盘以及高温回流温度曲线要求,符合AEC-Q200认证.

2520mm体积贴片晶振适用于汽车电子领域的表面贴片型石英晶振,本产品已被确定的高信赖性适合用于汽车电子部件,车载晶振在严酷的环境条件下也能发挥稳定的起振特性,晶振本身具有耐热,耐振,耐冲击等优良的耐环境特性,满足无铅焊接的高温回流温度曲线要求,符合AEC-Q200认证.

插件晶振适合用于比较低端的电子产品,比如儿童玩具,普通家用电器,即使在汽车电子领域中也能使产品高可靠性的使用.如车载晶振,并且可用于安全控制装置的CPU时钟信号发生源部分,好比时钟单片机上的石英晶振,在恶劣严酷的环境条件下,晶振也能正常工作,具有稳定的起振特性,高耐热性,耐热循环性和耐振性等的高可靠性能.

小型表面贴片型贴片晶振,如车载晶振较适合使用在汽车电子领域中.也是特别要求高可靠性的引擎控制用CPU的时钟部分.小型,薄型具备强防焊裂性,石英晶体在恶劣严酷的环境条件下也能发挥稳定的起振特性,产品本身具有耐热,耐振,耐撞击等优良的耐环境特性,满足无铅焊盘以及高温回流温度曲线要求,符合AEC-Q200认证.

小型表面贴片型贴片晶振,"MA-505 40.0000M-C0:ROHS"如车载晶振较适合使用在汽车电子领域中.也是特别要求高可靠性的引擎控制用CPU的时钟部分.低频晶振可从4.0MHz起对应,小型,薄型具备强防焊裂性,石英晶体在恶劣严酷的环境条件下也能发挥稳定的起振特性,产品本身具有耐热,耐振,耐撞击等优良的耐环境特性,满足无铅焊盘以及高温回流温度曲线要求,符合AEC-Q200认证.

小型表面贴片型贴片晶振,"MA-406 25.0000M-C3:ROHS"如车载晶振较适合使用在汽车电子领域中.也是特别要求高可靠性的引擎控制用CPU的时钟部分.小型,薄型具备强防焊裂性,石英晶体在恶劣严酷的环境条件下也能发挥稳定的起振特性,产品本身具有耐热,耐振,耐撞击等优良的耐环境特性,满足无铅焊盘以及高温回流温度曲线要求,符合AEC-Q200认证.

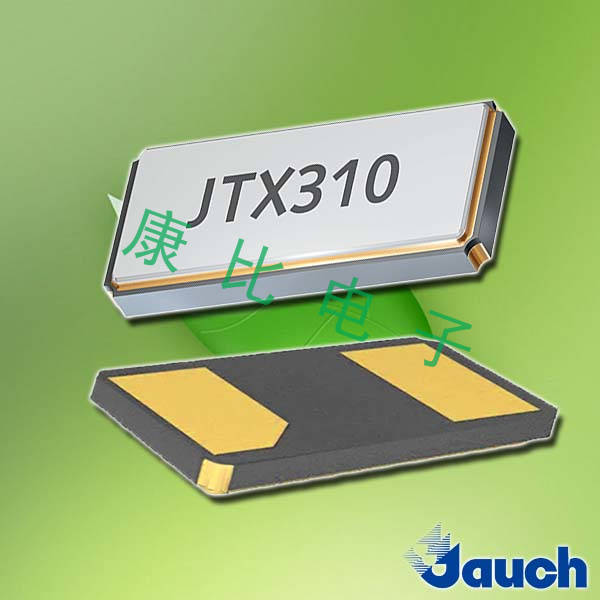

超薄型具备强防焊裂性,石英晶体在极端严酷的环境条件下也能发挥稳定的起振特性,是一款公认的车载晶振产品,产品本身具有耐热,耐振,耐撞击等优良的耐环境特性,满足无铅焊接以及高温回流温度曲线要求,符合AEC-Q200标准.

Skyworks以射频创新为核赋能5G大规模物联网应用普及

5G大规模物联网的普及,是数字经济发展的必然趋势,也是推动千行百业数字化转型的核心动力,更是实现"万物互联"智能时代的重要基础.作为全球射频半导体领域的领军企业,Skyworks凭借深厚的技术积淀,全面的产品矩阵,开放的产业协同理念,以射频创新破解行业痛点,以全场景解决方案激活应用价值,以产业协同加速普及进程,成为推动5G大规模物联网应用普及的核心力量,用射频技术为5GIoT产业发展注入强劲动力.从核心射频器件研发到全场景解决方案优化,从产业协同到场景落地,Skyworks始终以创新为核心驱动力,坚守"技术创新驱动无线通信变革"的使命,推动射频技术与5GIoT的深度融合,助力物联网产业实现规模化,高质量发展.

Skyworks与华硕强强联合推出全球首款超快速Wi-Fi6E扩展频段路由器

当前,Wi-Fi6E技术正进入规模化发展的关键阶段,6~7GHz扩展频段的启用为无线网络升级提供了广阔空间,而随着AIoT,AR/VR,云计算等技术的持续演进,用户对无线网络的性能要求将进一步提升.Skyworks与华硕将继续坚守创新初心,深化战略合作,聚焦Wi-Fi技术的迭代升级,推动无线网络向更快,更稳,更智能,更普惠的方向发展.Skyworks将持续加大Wi-Fi射频技术的研发投入,聚焦Wi-Fi6E及下一代Wi-Fi技术的创新,进一步优化前端模块的性能,提升集成度,降低功耗,扩大频段覆盖,推出更多适配不同场景的高性能射频解决方案,为终端设备厂商提供更加强大的技术支撑.同时,将持续深化与产业链伙伴的合作,推动射频技术与终端设备的深度融合,加速Wi-Fi6E技术的规模化普及,助力数字基础设施的升级.华硕将继续发挥其在网络设备领域的优势,依托AiMesh等核心技术,持续优化Wi-Fi6E路由器的性能与用户体验,推出更多适配家庭,办公,电竞等不同场景的产品,满足用户的多元化需求.同时,将进一步加强与Skyworks等核心合作伙伴的技术协同,探索Wi-Fi技术与AI,边缘计算等技术的融合创新,打造更智能,更高效的网络解决方案,引领数字生活方式的变革.

彼得曼32.768K有源晶振的优势,Time requirements in modern metering applications have massively increased in the last few years. The usual requirement in modern metering applications is a time offset of 1 hour after 7 years. It should also be possible for the operating temperature range of the application to comply with this value. 1 hour max. after 7 years corresponds to a frequency tolerance of ±16 ppm absolute at 32,768 kHz. It is no longer possible for conventional 32,768 kHz oscillating crystals to meet these requirements.

On the one hand, this is because 32,768 kHz are only available with a frequency tolerance of ±10ppm at +25°C, on the other hand, the temperature stability over a temperature range of -40/+85°C is more then -180 ppm. Moreover, ageing of approx. ±30 ppm after 10 years must be taken into account when calculating accuracy. In the worst case, a 32,768 kHz crystal has a maximum frequency stability of +40/-220 ppm (including adjustment at +25°C, temperature stability and ageing after 10 years). External circuit capacitance must be able to compensate any systematic frequency offset caused by the internal capacitance of the oscillator stage of the IC to be synchronised and by stray capacitance. The selection of a layout without external circuit capacitance for the 32,768 crystal involves a great risk because the accuracy of the 32,768 crystal can neither be corrected nor adjusted to suddenly changing PCB conditions during series production. Initially, the intersection angle for the 32,768 crystal was designed for optimal accuracy in wristwatches, and not for most of the applications for which it is used nowadays.

In order to meet the highly accurate time requirements, we as a clocking specialist offer the series ULPPO ultra low power 32,768 kHz oscillator. This oscillator can be operated with each voltage within a VDD range of 1.5 to 3.63 VDC. The specified current consumption is 0.99 µA. The temperature stability of ULPPOs is ±5 ppm over a temperature range of -40/+85°C. Frequency stability (delivery accuracy plus temperature stability) is ±10 ppm, and ageing after 20 years is ±2 ppm. Thus the maximum overall stability of ULPPOs is ±12 ppm including the ageing after 10 years. These are industry best parameters.

No external circuit capacitance is required for the circuiting of the ultra small housing (housing area: 1.2 mm2). The input stage of the IC installed in the ULPPO independently filters the supply voltage. Compared to crystals, ULPPOs save a lot of space on the printed circuit board so that the packing density can be increased, and smaller printed circuit boards can be designed. The adjustment of the amplitude further reduces the power consumption of the ULPPO.

For space calculations, both external circuit capacitances for a crystal on the printed circuit board must also be taken into account. With its two external circuit capacitances, even the smallest 32,768 kHz crystal requires more space on the PCB than ULPPOs do.

Moreover, very small 32,768 kHz crystals have very high resistances which usually cannot be safely overcome by the oscillator stages to be synchronised because the oscillator stages of the ICs or RTCs to be synchronised have very high tolerances as well. Therefore, sudden response time problems in the field might occur which can be ruled out with ULPPOs. Thus, the safe operation of the application is possible with ULPPOs under all circumstances.

Oscillator stages consume a lot of energy to keep a 32,768 crystal oscillating. Usually, the input stage of the MCU can be directly circuited with the LVCMOS signal of the ULPPO (usually Xin). Thus the input stage of the MCU can be deactivated (bypass function) so that the energy saved can be used for the calculation of the system power consumption of the meter. Moreover, ULPPOs are able to synchronise several ICs at a time. Due to the very high accuracy of the ULPPO, less time synchronisations are required, which also saves system power.

Of course, ULPPOs can be used in any applications which require miniaturised ultra low power 32,768 kHz oscillators such as smartphones, tablets, GPS, fitness watches, health and wellness applications, wireless keyboards, timing systems, timing applications, wearables, IoT, home automation, etc. Due to the high degree of accuracy of 32,768 kHz oscillators, the standby time or even the hypernation time in hypernation technology applications can be significantly increased so that a high amount of system power can be saved due to the significantly lower battery-intensive synchronisation cycles. Thus the 32,768 kHz oscillator is the better choice compared to 32,768 kHz crystals. Ultra low power 32,768 kHz oscillators are available with diverse accuracy variations – see also the ULPO-RB1 and -RB2 series.

不断精进自我的优质制造商彼得曼公司,致力于开发大量高质量的产品,随着近几年来,现代计量应用的时间要求大幅提高。现代计量应用的通常要求是7年后时间偏移1小时。应用的工作温度范围也应符合该值。最多1小时。7年后对应于32,768kHz下16ppm绝对值的频率容差。传统的32,768 kHz振荡晶体不再可能满足这些要求。彼得曼32.768K有源晶振的优势.

一方面,这是因为32,768kHz仅在+25°C时具有10ppm的频率容差,另一方面,在-40/+85°C温度范围内的温度稳定性高于-180ppm。此外,老化约。计算精度时,必须考虑10年后的30ppm。最差情况下,32.768K有源晶振的最大频率稳定性为+40/-220 ppm(包括+25°C时的调整、温度稳定性和10年后的老化)。外部电路电容必须能够补偿由要同步的ic振荡器级的内部电容和杂散电容引起的任何系统频率偏移。为32,768晶振选择无外部电路电容的布局包含很大的风险,因为在批量生产期间,32,768晶振的精度既不能校正也不能调整以适应突然变化的PCB条件。最初,32,768英寸晶体的交叉角度是为手表的最佳精度而设计的,而不是为如今使用它的大多数应用而设计的。

领先同行高加音频晶体打开沉浸感的新维度,Unleashing the Power of Audio Crystals: Elevating Your Sound Experience

Introduction

In the realm of audio technology, a fascinating innovation has emerged - audio crystals. These remarkable crystals have revolutionized the way we perceive and experience sound. In this blog post, we will explore the enchanting world of audio crystals, delving into their capabilities, benefits, and how they have transformed our audio landscape.

Understanding Audio Crystals

Audio crystals are specialized components that possess unique properties for enhancing sound quality. These crystals are meticulously engineered to resonate at specific frequencies, allowing them to optimize audio performance across various devices and settings. By harnessing the inherent properties of these crystals, audio engineers can unlock the full potential of sound reproduction.

The Science Behind Audio Crystals

Audio crystals operate on the principle of piezoelectricity. This phenomenon occurs when certain crystals generate an electric charge under mechanical stress, such as when subjected to vibrations or pressure. By strategically incorporating these crystals into audio systems, the vibrations caused by sound waves can be efficiently converted into electrical signals, resulting in clearer, more immersive sound reproduction.

Benefits of Audio Crystals

The integration of audio crystals brings about several noteworthy benefits:

The Future of Audio Crystals

As technology continues to advance, the potential of audio crystals is boundless. With ongoing research and development, we can expect even further advancements in sound reproduction, leading to more refined audio experiences for enthusiasts and professionals alike. The integration of audio crystals into emerging technologies, such as virtual reality and augmented reality, holds exciting possibilities for immersive audio in the future.

In conclusion, audio crystals have emerged as a game-changing innovation in the world of audio technology. By harnessing their unique properties, we can unlock new dimensions of sound quality and immersion. As we continue to explore the endless possibilities of audio crystals, one thing is certain - the future of sound has never sounded brighter.

释放音频晶体的力量:提升您的声音体验

介绍

在音频技术领域,一项引人入胜的创新出现了——音频晶体。这些非凡的晶体彻底改变了我们感知和体验声音的方式。在这篇博文中,我们将探索音频晶体的迷人世界,深入了解它们的功能、优势,以及它们如何改变了我们的音频格局。

了解音频晶体

音频晶体是一种特殊的部件,具有增强音质的独特性能。这些压电石英晶体经过精心设计,可在特定频率下共振,从而优化各种设备和设置的音频性能。通过利用这些晶体的固有特性,音频工程师可以释放声音再现的全部潜力。

音频晶体背后的科学

音频晶体根据压电原理工作。当某些晶体在机械应力下产生电荷时,例如受到振动或压力时,就会出现这种现象。通过战略性地将这些晶体融入音频系统,声波引起的振动可以有效地转换为电信号,从而实现更清晰、更身临其境的声音再现。

JAUCH JXS系列石英晶体说明书,作为高质量元器件供应商之一的JAUCH公司,主要通过向广泛应用市场提供自身的价值,并为广大用户解决在晶体行业所遇到的问题点,以及提供完美的石英晶振解决方案,使得其能够快速与用户建立起亲密的合作关系,随着自身对于行业的了解,低成本高质量的产品必然会成为市场的刚需,JAUCH公司便利用自身的资源,专注于打磨高质量的产品,随之长期积累,以及自身的不懈努力,如今取得不错的成果,并发布系列优质的产品。

“如果苹果制造了一台搅拌机,那就是它”——英美在线新闻门户网站Mashable一针见血。谈到美学和产品设计,搅拌机“米洛”,由立陶宛初创企业米洛电器,离库比蒂诺的伟大偶像很近。

除了屡获殊荣的设计,“米洛”背后的技术尤为突出。专利的“磁力空气驱动”技术是该应用的核心。与其他类似设备相比,“米洛”杯和基站仅通过磁力相互连接;这意味着从安装在搅拌机底座上的发动机到安装在杯子里的叶片的动力传输,100%是通过这种磁性连接实现的。

由于其创新技术,该公司自2016年成立以来,已从各种投资者那里筹集了约140万欧元。Jauch Quartz也做出了自己的贡献:JXS系列的两个Jauch组件确保了“米洛”控制电子设备的精确计时。

“我们的水晶JXS系列使用AT切割石英坯件。Jauch Quartz的销售主管Steffen Fritz解释说:“因此,它们非常适合产生兆赫范围内的精确频率。米洛使用两种不同规格的JXS32压电石英晶体。Steffen Fritz说:“它们确保搅拌机的启停功能精确到毫秒。JAUCH JXS系列石英晶体说明书.

“与的关系米洛电器是由我们的立陶宛合作伙伴建立的埃尔格塔斯蒂芬·弗里茨回忆道。从那一刻起,一切都变得非常快。创始人知道他们想要什么,我们能够立即交付——有时就是这么简单。"

专用于物联网计量的6G模块晶体MS1V-T1K-32.768kHz-12.5pF-10PPM-TA-QC-Au,这是一家勇于创新,并持续保持成长力的制造商微晶公司,对于晶体的了解远远超越同行,凭着自身的创新能力,以及敢于不断挑战的精神,开发一系列高质量的产品,并得到无数用户的好评,随着市场需求增长,发布编码MS1V-T1K-32.768kHz-12.5pF-10PPM-TA-QC-Au,型号MS1V-T1K,尺寸为2020mm,频率为32.768KHZ,负载电容为12.5pF,精度为10ppm,MS1V-T1K是一种低频表面安装技术的石英晶体单元,它包含了一个音叉的石英晶体谐振器。它在真空密封的方形金属罐中工作。

贴片石英晶振产品特征:密封性保证了高稳定性。高冲击和抗振动能力。经过焊接的表面安装技术包。优良的铅共面性的表面安装。符合RoHS标准。产品主要应用范围:物联网计量、可穿戴设备、医疗保健、消费类电子产品等领域。

对于Micro Crystal来说,没有什么比用高性能超低功耗组件培养创新精神更重要的了。丰富的评估板和资源支持不断扩大的无源晶体产品组合,帮助工程师创造未来的产品。

威世OSC晶振XOSM-573-B-E-40M专用于无线发射塔,Vishay是一家十分知名的供应商,致力于为用户提供具备成本效益的优质产品,经过长期的积累,Vishay公司利用自身的优势,针对开发编码XOSM-573-B-E-40M,型号XOSM-573是一款贴片型轻薄型的有源晶振,XO时钟振荡器,OSC晶振,频率为40.000MHz,尺寸为7.0 x 5.0x1.6mm,电压为3.3 V,表面贴装振荡器,产品具备低电压低抖动高性能的特点,比较适用于5G基站,航空电子,无线发射塔,智能家居,仪器设备,测试测量,小型设备等领域。

The Vishay journey began with one man, Dr. Felix Zandman, and a revolutionary technology. From there we would grow and strengthen over decades, arriving where we are today: one of the world’s most trusted manufacturers of electronic components. From discrete semiconductors to passive components; from the smallest diode to the most powerful capacitor, Vishay’s breadth of products is the very foundation that brings modern technology to life, every day, for everyone. We call it The DNA of tech.™

This DNA is more than infrastructure for today’s most vital electronic products, it’s a platform to enable growth. Vishay is well-positioned to propel such timely macroeconomic growth drivers as sustainability, connectivity and mobility. Through R&D, manufacturing, engineering, quality, sales and marketing, we generate the essential components that enable inventors and innovators to create new generations of products—ones that span many sectors: automotive, industrial, consumer, computer, telecommunications, military, aerospace, and medical.

Together with the manufacturers of today and tomorrow’s most compelling electronic innovations, names you know, we are enabling next level automation in factories, the electrification of the automobile, 5G network technology, and the rapid expansion of connectivity across everything (IoT) to highlight a few areas of strong growth. This diversity of opportunity is the reason Vishay has thrived, and why we are driven to be the DNA behind the success of our customers and partners and to be part of making a future that’s safer, sustainable and more productive.

Vishay之旅始于一个人Felix Zandman博士和一项革命性的技术。从那时起,我们将在几十年的时间里不断发展壮大,达到今天的位置:世界上最值得信赖的电子元件制造商之一。从分立半导体到有源晶体振荡器;从最小的二极管到最大功率的电容器,Vishay的广泛产品为每个人的日常生活带来了现代技术。我们称之为技术的DNA。™